Improve Efficiencies for Power Transmission and Your Servo Motor

Choose the right servo motor coupling for your application

Matching the coupling to the motor is essential to optimizing performance for any application. Candy Controls offers a wide variety of servo couplings to satisfy the growing needs of the motion control industry. Candy’s line of precision, zero-backlash couplings has expanded with four new additions:

- CL23 Series high response coupling

- CL24 Series double clamp disc coupling

- CL25 Series Oldham coupling with stainless steel hubs and a copper insert

- CL26 Series steel disc coupling with locking assembly

All are highly precise flexible shaft couplings, ideal for applications requiring high speed, torque and rigidity. The specific design and performance features for each is provided below to help you select the best coupling for your particular motion control application.

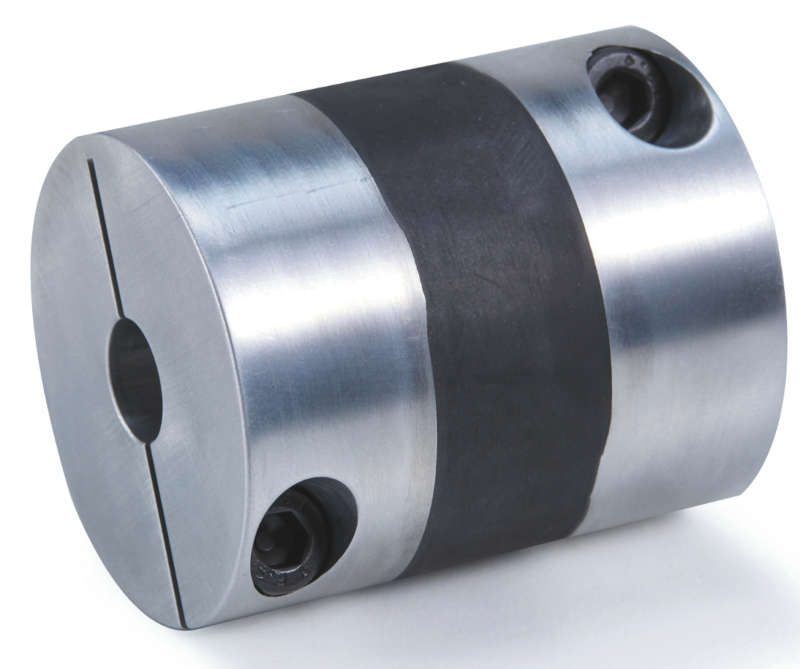

CL23 Series high response coupling

In a servo motor system, productivity and minimum delays are the key factors. All

the components must be adapted to fit the command execution accurately. For

example, a command can try to make the actuator reach a predetermined position,

but a delay can occur due to the stabilization time of the system. Because the

program will continue only when the position is reached and the actuator stopped, it is essential to minimize this stabilization time in order to improve productivity.

High response couplings are the best choice for optimal performance in servo

systems and ball screw applications. They can accommodate application speeds up

to 42,000 rpm and reduce “hunting”, a phenomenon that occurs when the system is

attempting to minimize error between the actual and commanded positions. The lag

between the error detection and correction causes a periodic oscillation between

overshooting and undershooting the target position. High response couplings allow

the system to react quickly to errors and to reduce the delay time.

Servo systems benefit from the high torque transmission with zero backlash in high

response couplings. Plus, their intermediate rubber elastomer body between two

aluminum hubs gives the coupling a high damping ratio to absorb vibrations and

provides electrical insulation.

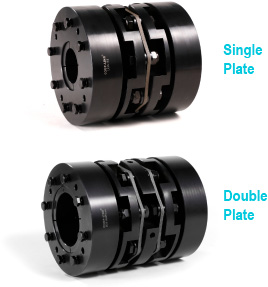

CL24 Series double clamp disc coupling

The double clamp disc coupling is a heavy duty version of the classic disc coupling.

Double clamp disc couplings have a steel body instead of an aluminum one, and

the shafts are secured on each side by a double clamping connection. With a

thicker plate spring made with more metallic layers than classic couplings, they are

an excellent choice when high rigidity and large torque transmission are needed.

The heavy duty design also allows the absorption of angular misalignment and

shaft endplay, while allowing the coupling to operate in temperatures between

-80 to 300 ˚C and in high impact situations. Its efficient torque transmission

properties deliver zero backlash in both single and double disc designs; with the

double disc accommodating more misalignment.

CL25 Series Oldham coupling with stainless steel hubs and a copper insert

Traditional Oldham couplings consist of two toothed aluminum hubs connected to

an elastomer rubber center disc. They are perfect for accommodating high amounts

of parallel misalignment and axial misalignment in high torque transmission

applications and have zero backlash.

Stainless steel hubs and a copper insert provide several advantages over the

classic aluminum and rubber design. They offer the same simple configuration

which makes it easy to assemble, but the higher durability of the center disc greatly

reduces wear, allowing the coupling to maintain zero backlash for a longer period of

time compared to rubber. Although the rubber insert works well with greater parallel

misalignment and higher speeds, the stainless steel and copper design leans more

toward high torque operations that require excellent torsional stiffness and response

and lower speeds.

Because it can be easily washed down, the stainless steel and copper design lends

itself to applications where there are frequent and intensive machine cleaning

processes. It’s perfect for the food and beverage and medical industries.

CL26 Series steel disc coupling with locking assembly

The CL26 is a steel disc coupling with a locking assembly shaft attachment. It

features a steel body with thicker plate springs than classic disc couplings, and

each shaft end is locked to the coupling through a shrink disc and screw

connection. The combination of a steel body, thicker plate springs, and a stronger

connection to the shafts increases rigidity and torque transmission while still

maintaining zero backlash and flexible shaft characteristics. Available in a single or

double disc version, an additional set of plate springs in the double disc version

increases coupling’s ability to accommodate misalignment.

In comparison to clamp and keyway systems, the locking assemblies coupling

delivers an even pressure distribution while being entirely backlash free. Angularity

errors between the two shafts, as well as shaft endplay, are corrected by the central

stainless steel spring plate. Its compact design and high response and torque

capacities make it ideal for servo motor applications.

Candy Controls

Candy Controls