Precision Spiral Bevel Gearboxes

Quick Facts

- CT is 100% stainless steel and the CTB series is standard steel

- High-torque, low-backlash right-angle gearboxes

- Backlash from 6 arc minutes

- Flexible design accommodates multiple shaft options

- Metric and NEMA motor adaptors for virtually any type of motor

- Ratios from 1:1 up to 500:1 with planetary stages

- 2-year product warranty

Product Overview

These right-angle gearboxes feature precision, ground spiral bevel gear sets for applications that require accuracy and repeatability. This series is available in combination with planetary stages to achieve ratios up to 500:1. Motor adaptor housings are also available to mount a variety of metric and NEMA motors.

| Precision Spiral Bevel Gearboxes | Frame Sizes | Output Torque | Ratios 1-Stage |

Ratios 2-Stage |

Ratios 3-Stage |

Backlash 1-Stage (arc-min) |

Backlash 2-Stage (arc-min) |

Backlash 3-Stage (arc-min) |

CT/ CTB |

9: 65mm – 280mm | 12 Nm – 3200 Nm | 1, 1.5, 2, 3, 4, 5 Bevel Only | – | – | <6 | – | – |

CT/ CT/CTB-FL |

9: NEMA 23, 34, 42, 56, 75, Metric 60, 90, 115, 142mm | 9 Nm – 423 Nm | 1,1.5, 2, 3, 4, 5 | 7, 10, 15, 20, 25, 35, 50 | 70, 100, 125, 150, 200, 250, 350, 500 | <6 | <8 | <10 |

MULTIPLE GEARBOX CONFIGURATIONS

CT-L/-L1/-R1

CT-FL/-FL1/-FR1

CT-H/-C

CT-FH/-FC

CT-4M/-LM/-RM

CTB-L/-L1/-R1

CTB-FL/-FL1/-FR1

CTB-H/-C

ATB-FH/-FC

CTB-4M/-LM/-RM

Design Highlights

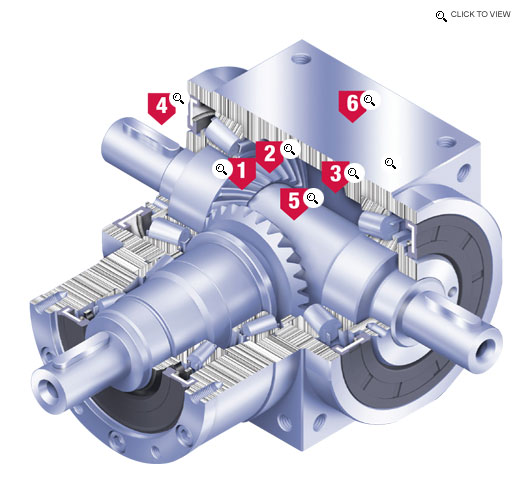

High-precision, ground spiral bevel gear sets incorporate helical geometry for smooth, accurate and repeatable rotation. Gears exceed in DIN 5.

Gears are carburized to provide a consistent tooth hardness for superior wear resistance and durability.

Steel Housing This housing is designed for maximum rigidity and corrosion resistance and offers multiple precision-machined surfaces for ease of installation.

Input/Output Shafts Multiple input and output configurations are available to meet a wide variety of applications.

The precision right angle gearboxes incorporate Nyogel 792D synthetic grease and are lubricated for life. Food grade grease is available upon request.

Design flexibility offers a number of options including; single shaft left or right, through shaft, hollow shaft, adaptors to accommodate most metric and NEMA motors, and multiple planetary stages to achieve ratios up to 500:1.

Candy Controls

Candy Controls