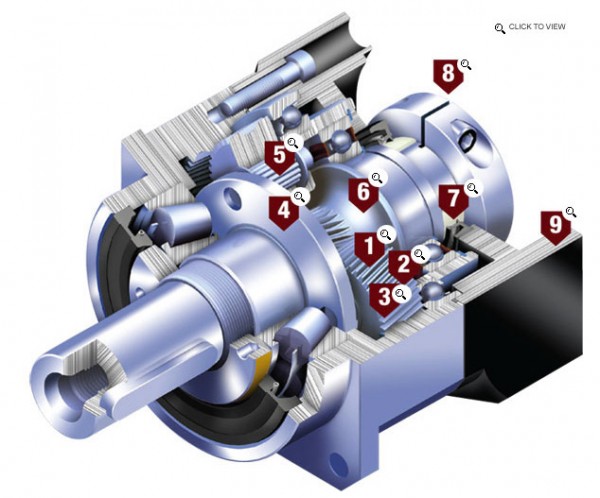

Precision Helical Planetary Gearboxes

Quick Facts

- 33% more tooth contact with helical gear technology

- Low backlash with up to 3 precision classes available

- Ratios from 3:1 up to 10,000:1

- Metric and NEMA models for virtually any type of motor

- Stainless steel models available

- Drop-in units for a number of competitors

- 5-year product warranty

Product Overview

This series features helical planetary gear technology that provides maximum gear-to-gear tooth contact for high-torque, low-backlash applications. Up to three different precision classes are available, with the highest class achieving less than 1 arc minute backlash. In-line and right-angle units are available with motor adaptor housings to accommodate virtually any type of metric or NEMA motor.

| Series | Performance | Backlash | Frame Sizes | Output Torque | Ratios – 1-Stage | Ratios – 2-Stage | Ratios – 3-Stage | Ratios – 4-Stage |

| Maximum | <1 arcmin | 90 mm – 450 mm | 315 Nm – 13,875 Nm | 5.5 | 22, 27.5, 38.5, 55 | 88, 110, 154, 220 | ||

CAPK CAPK |

Maximum | <2 arcmin | 110 mm – 450 mm | 95 Nm – 14,010 Nm | 4, 5.5, 8, 11, 16, 20, 22, 27.5, 28, 38.5, 40, 55 | 64, 88, 100, 110, 137.5, 140, 154, 160, 200, 220, 280, 385 | 400, 440, 500, 550, 700, 770, 1000, 1078, 1400, 1540, 1600, 2000, 2695, 2800, 3850, 4000, 5500 | |

CB CB |

Advanced | <1, <3, <5 arcmin | 42 mm – 220 mm | 14 Nm – 2,000 Nm | 3, 4, 5, 6, 7, 8, 9, 10 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | ||

CBR CBR |

Advanced | <2, <4, <5, <6, <7, <9 arcmin | 42 mm – 220 mm | 14 Nm – 2,000 Nm | 3, 4, 5, 6, 7, 8, 9, 10, 14, 20 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 | ||

CD CD |

Advanced | <1, <3, <5 arcmin | 47 mm – 255 mm | 14 Nm – 2,000 Nm | 4, 5, 7, 10 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | ||

CDR CDR |

Advanced | <2, <4, <6, <7, <9 arcmin | 47 mm – 255 mm | 14 Nm – 2,000 Nm | 4, 5, 7, 10, 14, 20 | 20, 25, 30, 35, 40, 50, 70, 100, 140, 200 | ||

CDS CDS |

Advanced | <1, <3, <5 arcmin | 47 mm – 255 mm | 14 Nm – 2,000 Nm | 4, 5, 7, 10 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | ||

CE CE |

Optimized Economy | <1, <3, <5 arcmin | 50 mm – 235 mm | 14 Nm – 2,000 Nm | 3, 4, 5, 6, 7, 8, 9, 10 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | ||

CER CER |

Optimized Economy | <10, <14 arcmin | 50 mm – 235 mm | 14 Nm – 2,000 Nm | 3, 4, 5, 6, 7, 8, 9, 10, 14, 20 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 | ||

CF CF |

Advanced | <1, <3, <5 arcmin | 42 mm – 220 mm | 14 Nm – 2,000 Nm | 3, 4, 5, 6, 7, 8, 9, 10 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | ||

CFR CFR |

Advanced | <2, <4, <5, <6, <7, <9 arcmin | 42 mm – 220 mm | 14 Nm – 2,000 Nm | 3, 4, 5, 6, 7, 8, 9, 10, 14, 20 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 | ||

CFH CFH |

Premium | <1, <2, <3 arcmin | 60 mm – 240 mm | 24 Nm – 4,090 Nm | 3, 4, 5, 7, 10 | 16, 20, 25, 28, 35, 40, 50, 70, 100 | ||

CFHK CFHK |

Premium | ≤ 1 – ≤ 3 arcmin | 60 mm – 240 mm | 12 Nm – 3,340 Nm | N/A | 4, 5, 7, 8, 10, 12, 16, 20, 25, 28, 35, 40, 50, 70, 100 | 48, 64, 84, 100, 125, 140, 175, 200, 250, 280, 350, 400, 500, 700, 1,000 | 1,225, 1,400, 1,750, 2,000, 2,800, 3,500, 5,000, 7,000, 10,000 |

CFX CFX |

Advanced | <5, <7 arcmin | 42 mm – 180 mm | 14 Nm – 1,200 Nm | 3, 4, 5, 6, 7, 8, 9, 10 | 12, 15, 16, 20, 25, 28, 30, 32, 35, 40, 45, 50, 60, 70, 80, 90, 100 | ||

CFXR CFXR |

Advanced | <6, <9 arcmin | 42 mm – 180 mm | 12 Nm – 1,200 Nm | 3, 4, 5, 6, 7, 8, 9, 10, 12, 14, 16, 20 | 12, 15, 16, 20, 25, 28, 30, 32, 35, 40, 45, 48, 50, 60, 64, 70, 80, 90, 100, 120, 140, 160, 180, 200 | ||

CH CH |

Premium | ≤ 1 – ≤ 2 arcmin | 64 mm – 450 mm | 12 Nm – 3,340 Nm | 4, 5, 7, 10 | 16, 20, 21, 25, 28, 31, 35, 40, 46, 50, 61, 70, 91, 100 | ||

CHK CHK |

Premium | ≤ 2 – ≤ 3 arcmin | N/A | 24 Nm – 5,615 Nm | N/A | 4,5,7,8,10, 12, 15, 16, 20, 25, 28, 35, 40, 49, 50, 70, 100 | 21, 31, 46, 64, 84, 91, 100, 125, 140, 175, 200, 250, 350, 500, 700, 1,000 | 1,225, 1,400, 1,750, 2,000, 2,800, 3,500, 5,000, 7,000, 10,000 |

Design Highlights

Candy Controls

Candy Controls