FEATURED IN TECH BRIEFS:

HYPOID GEARS – A LONG WAY FROM TRUCK AXLES TO MOTION CONTROL

About Hypoid Gears

In this article we explain what hypoid gears are, how they are used, and their benefits and drawbacks compared to standard bevel gears and worm gears in a wide range of motion control applications.

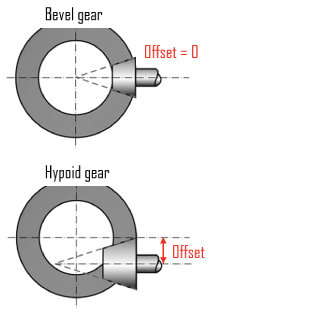

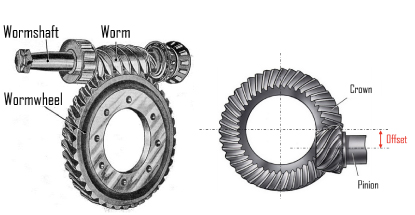

Invented in the 1920s, hypoid gears are a type of bevel gear that are used to transmit rotational power, or torque, between two shafts at right angles. The difference between hypoid gears and standard bevel gears is that the mating gear shafts for hypoid gears do not intersect, because the smaller gear shaft (pinion) is offset from the larger gear shaft (crown).

The Benefits of Hypoid Gears

The primary benefit of using hypoid gears instead of normal bevel gears is that they can transmit a greater amount of torque while remaining compact in size. Bevel gears, on the other hand, are typically more efficient, making them the better choice for applications where small size isn’t critical.

When compared to worm gears, hypoid gears are faster and more efficient, leading to energy savings. Plus, the efficiency stays constant across multiple ratios and speeds, and hypoid gears can achieve very low backlash.

> Read the Full Story about Hypoid, Standard Bevel, and Worm Gears

Candy Controls

Candy Controls