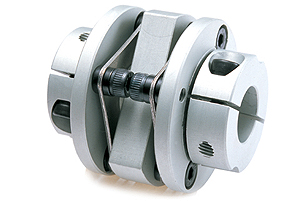

Disc Couplings For Power Transmission and Motion Control

Zero-Backlash, Excellent Torsional Stiffness

When it comes to power transmission and motion control applications, making the right shaft connection is critical to ensuring the smooth and efficient transfer of power and motion from one shaft to another. Most couplings, by design, are either used in power transmission or motion control applications, but typically not both. Zero-backlash, flexible shaft disc couplings, however, have “hubs” firmly connected to driving and driven shafts in each of these worlds because of the following design traits that are important to both industries:

1. High Torque Capacity

Disc couplings are designed to handle high torque loads typical of power transmission applications. As a result of their inherent accuracy and rigidity, combined with torque capacity, disc couplings have become a popular solution for a variety of motion control applications.

2. Zero-Backlash, Excellent Torsional Stiffness

Zero-backlash and torsional stiffness are critical traits in most power transmission and motion control applications because of positional integrity, ensuring that both power and motion are transmitted without loss or distortion. Backlash is physical error or play that can be caused by coupling components or in the connection to the shafts. Torsional stiffness in a coupling helps prevent twisting or wind-up under load. Zero-backlash, torsionally stiff disc couplings ensure positional accuracy and repeatability.

3. Misalignment Compensation

Another key benefit of disc couplings is their ability to compensate for misalignments, particularly angular and axial. The ability to absorb misalignment reduces stress on more expensive connected components The ability to absorb misalignment reduces stress on connected components, extends their life, and minimizes downtime due to maintenance and repairs.

4. High Speed/Low Inertia

While speed and inertia characteristics can be important for power transmission applications, they are particularly important attributes in the world of motion control. The moment of inertia is a data point that describes how easily a body can be rotated about its axis. Low inertia couplings allow a system, a servo motor system for example, to be tuned to a higher level of performance. Inertia becomes a more important factor for applications involving high speeds, changing speeds and/or direction of rotation.

5. Corrosion Resistance

Disc couplings are available in a variety of materials including aluminum, steel, stainless steel and other corrosion resistant alloys. This is essential for applications in harsh environments or those requiring frequent washdowns. The durability of these materials is a critical component of product quality, longevity and reliability.

6. Simple Installation and Maintenance

Another benefit of disc couplings is their ease of installation and maintenance, making them a user-friendly, cost-effective solution for both power transmission and motion control applications. Their simple, but rugged design helps reduce labor and maintenance costs, machine downtime, and operational disruptions resulting in higher machine productivity.

These popular design features make single and double-disc couplings a great solution for shaft connections in the following power transmission and motion control applications:

Power Transmission

Rotary Equipment – pumps, compressors, fans

Electric Motors – connect motor and generator shafts

Marine & Propulsion – drive shafts, propellers

Industrial Machinery – conveyors, extruders

Paper & Pulp – rollers, conveyors

Agricultural Machinery – harvesters, tractors

Oil & Gas – compressors, pumps

Mining – crushers, heavy duty equipment

Renewable Energy – wind turbines, solar tracking

Railway & Transportation – connection to axles

Testing & Measuring – compression, resistance

Motion Control

CNC Machining – spindles, ball screws

Robotics – servo actuators, joints, arms

Medical Equipment – diagnostic, imaging devices

Food & Beverage – processing, filling machines

Pharmaceutical/Lab – robotics, handling

Automated Manufacturing – semiconductors

Aerospace & Defense – component orientation

Packaging Machinery – cappers, cartoners

Web Converting – printing, cutting, coating

Optical & Photonics – alignment and positioning

Entertainment industry – camera, stage motion

Disc couplings are a reliable, versatile solution for shaft connection applications in both the power transmission and motion control industries. Their exceptional torque capacity, torsional stiffness, misalignment compensation, high speed, corrosion resistance and ease of installation and maintenance characteristics make disc couplings a preferred choice for mechanical engineers across the industrial manufacturing spectrum. When it comes to ensuring the efficiency, accuracy, durability and overall productivity of your machinery, disc couplings prove to be the right connection.

Candy Controls

Candy Controls