Do You Need A Custom Solution?

Candy Controls Has The Answer

Have you ever found yourself grappling with the age-old dilemma of fitting a square peg into a round hole? Whether it’s in daily life or professional endeavors, we’ve all experienced situations where the standard solutions simply don’t fit. If you’re currently working on a machine design or retrofit project and facing challenges related to gearboxes, screw jacks, or shaft couplings, Candy Controls is here to offer tailored solutions designed to meet your specific requirements.

At Candy Controls, we specialize in the design and fabrication of custom automation components and systems catering to a diverse range of industrial automation, power transmission, and motion control applications. If you need a unique gearbox, screw jack, or shaft coupling, we excel in customizing bores, shaft diameters and lengths, material selection, and more to perfectly align with your project needs.

Our capabilities extend beyond mere customization; we also provide custom accessories, systems, and kits complementing our core products, thereby streamlining your design and procurement processes. Should your gearbox or screw jack need a special housing, Candy Controls can create new molds for castings and deliver functional prototypes within a 10-12 week timeframe. By optimizing design, fabrication, and assembly processes, we not only address the original component or system challenge but also help you save valuable time and resources.

Explore Our Range of Customized Solutions:

- Tailored Coupling Solutions: Whether it’s custom or mixed bores, face mount options, or custom coupling sizes, lengths, and materials, we’ve got you covered.

- Material Expertise: We specialize in incorporating stainless steel and other materials, along with offering various treatments to meet specific application and environmental requirements.

- Comprehensive Design Services: From custom shaft configurations and sizes to custom mounting configurations, we provide solutions tailored to your unique prototype or retrofit project specifications.

- Compact and Efficient Designs: Our expertise extends to designing motor mount flanges for more compact gearbox or screw jack designs, optimizing space utilization without compromising performance.

- Complete Kits and Systems: Experience the convenience of kits including motors, connecting shafts, pillow block bearings and couplings, professionally specified and curated to streamline your machine assembly process.

- Prototyping and Replacement Solutions: Ensure seamless integration into your design or retrofit project with modified and custom products for prototyping or as a replacement for obsolete or long lead time gearboxes, screw jacks or couplings.

Don’t let a “Square Peg” scenario impede your machine design progress.

Contact Candy Controls today by calling us at 847-588-2639 or email: info@candycontrols.com to discover how we can transform your unique challenges into practical, customized solutions.

Custom Solution Examples:

We are able to solve application problems with solutions that address custom sizes, specifications, materials, mounting options and more.

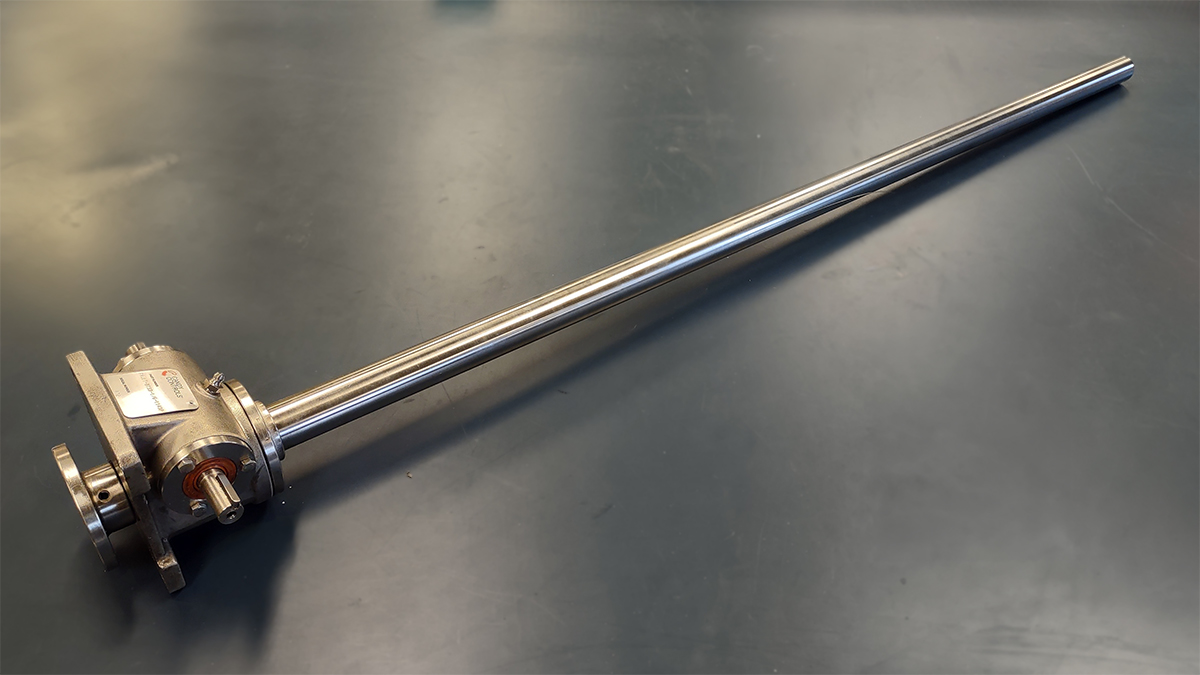

Custom Screw Jack

This inverted, keyed, 1 ton machine screw jack is fabricated from stainless steel (shafts, screw, lifting flange, housing and protective tube) and is used to apply pressure to test a proprietary material in a caustic manufacturing environment that is subject to wash downs.

(click on image to see larger view)

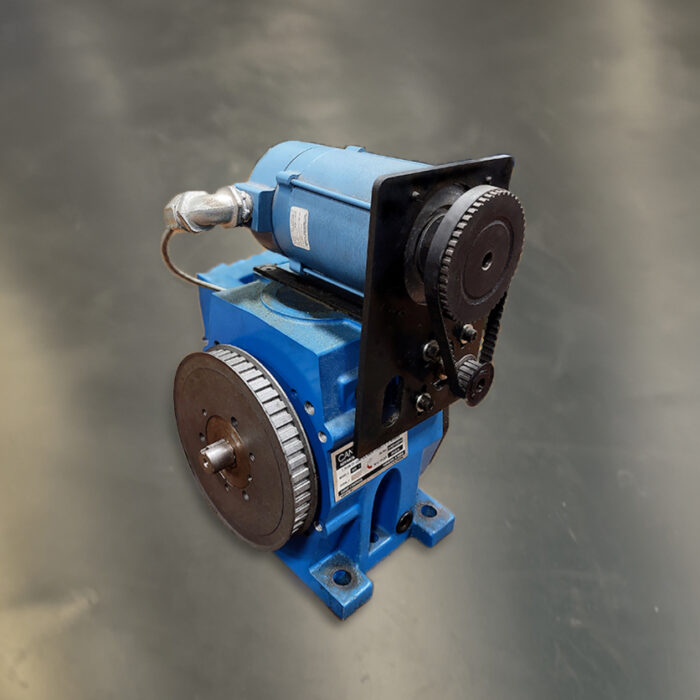

Custom Differential Gearbox

Differential gearbox assembly provided with open loop, AC, Slow Syn motor with custom mounting plate and 3:1 timing belt reduction to differential control shaft to achieve customer’s desired correction rate between input and output shafts. Gearbox includes timing belt pulley mounted to the input. This differential gearbox assembly is ready to drop into the client’s food packaging machine retrofit project providing infinite, bi-directional phase/timing control of a candy bar packaging machine; specifically the gearbox times a heated, rotating wheel that seals and cuts the ends of the pre-printed wrapper after its formed around the candy bar and sealed down its length.

(click on image to see larger view)

Custom Bevel Box

This custom bevel box was designed for an OEM in the transportation industry to help open and close automatic doors. The gearbox was modified with a custom shaft material to accommodate the customer’s 1 million cycle test requirement. The 1:1 bevel box was supplied with customized shaft lengths and diameters. The input shaft includes a custom key to mount the customer’s motor and the output shaft is extended and includes a snap ring for the customer’s brake attachment.

(click on image to see larger view)

Custom Coupling

The stainless steel coupling was designed for an OEM of mixing equipment. The customer needed a custom length, and needed the coupling made of 304 stainless steel. We designed and fabricate two different sizes of these stainless steel, rigid couplings specific to our customer’s needs.

(click on image to see larger view)

60 Years Of Industry Expertise Ready To Help You

At Candy Controls we take a hands-on approach in helping you select the right custom product for your specific application.

Ask us anything. Our extensive industry experience allows us to be able to uniquely understand your project needs. If you have specific questions about this product or anything in our product lines, send us an email , call (847) 588-2639, or talk to us via the live chat option in the bottom corner.

Candy Controls

Candy Controls