CONSIDER HARMONIC DIFFERENTIAL GEARBOXES FOR POSITIONING AND SPEED TRIMMING APPLICATIONS

A Harmonic Differential Gearbox? What is it?

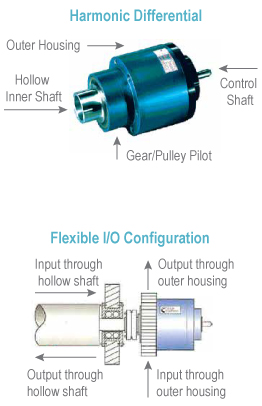

Harmonic Differential Gearboxes are shaft-mounted, phase-shifting transmissions used for precise rotary position and/or speed trimming control. When mounted to the end of a shaft, these phase-shifting gearboxes provide bi-directional, adjustable motion control for virtually any type of rotating process. For convenience, either the hollow inner shaft, or the outer housing (with drive gear, pulley or sprocket mounted to it) can be used as the differential input. The other main element is the control shaft that creates the differential action when rotated in one direction to the other. The control shaft input can be manual or motorized resulting in a mechanical or electro-mechanical position and speed control.

What would I use something like this for?

Harmonic Differential Gearboxes can be used to adjust the timing or position of just about any type of machine that incorporates rotating sprockets, pulleys and gears that drive a process or section of a machine.

Can you provide more specific application examples?

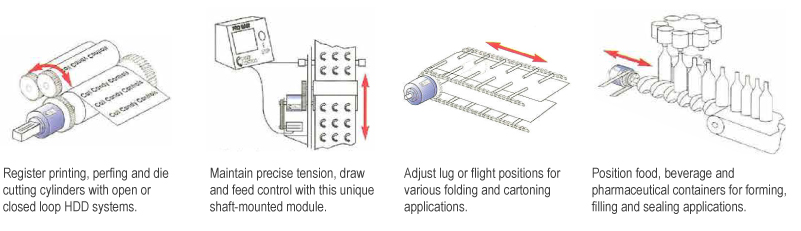

These gearboxes are commonly used to provide static or dynamic timing and adjustment of food/beverage/pharmaceutical processing machines, packaging machines, web printing and paper converting machines. There are a number of applications for Harmonic Differential Gearboxes, but here are the most common:

• Adjust position of chain flights or lugs that move product in assembly, processing, or packaging machines

• Position or speed trim conveyor belts to time food processing or packaging processes

• Adjust tooling that seals, crimps and/or cuts packaging around product, i.e. candy bars

• Control the timing and position of pusher heads that insert product into cartons or boxes

• Position feed or helix screws and the bottles or containers they move through filling machines

• Precisely control the position of printing cylinders on web fed printing presses

• Dynamic control of rotary die cutting cylinders to correct registration errors on web converting machines

• Overdrive or under-drive nip rolls to provide web tension for printing and packaging machines

• Provide draw control for chill rolls to relax webs leaving a hot air dryer

• Control the speed of unwind and rewind rolls on web fed equipment

• Level wind control for winding and spooling equipment common in the subsea energy industry

• Adjust the timing of two or more machines driven from a common motor or line shaft

Ok, it’s a timing gearbox. I don’t really understand the benefit. What’s all the excitement about?

The ability to adjust the timing or position of a machine section, or product within a machine section, while the machine is running or stopped, provides a number of benefits that will favorably impact your bottom line. Harmonic Differential Gearboxes help:

• Reduce downtime during machine startups and changeovers

• Less machine set-up time

• Increase product quality/precision/accuracy

• Reduce material waste

• Increase the overall productivity of existing machines or new machine designs

Interesting. Why wouldn’t I use a servo motor for these types of rotary motion control applications?

Servo systems offer many benefits, we are not arguing against servo technology. Mechanical, or electro-mechanical solutions offer a few benefits worth considering as well. Perhaps the largest of all is simplicity, other differential gearbox advantages might include:

• Simple to understand and operate

• User preference, some end-users prefer mechanically driven machines

• Lower upfront costs, lower ongoing maintenance costs

• Great for retrofits; easily incorporated into existing machines

• Less intrusive to an existing machine’s drive train; less retrofit risk

• Ideal control shaft ratios for high torque applications

• Precise, compact, low-backlash design

Some good points! Help me understand exactly how Harmonic Differential Gearboxes work?

The most popular Harmonic Differential Gearbox is the HDD Series. When the control shaft is held stationary on an HDD Series, the input and output will rotate in the same direction at a 1:1 ratio. If a rotation is applied to the control shaft, either manually or with a motor, a differential action occurs between the input and output making the HDD Series well-suited for positioning applications. This differential action, or positioning of the output relative to the input, also referred to as phase-shifting, is bi-directional depending on the direction of rotation on the control shaft. Once the tooling, or product, is in the proper position and the control shaft is stationary, the Harmonic Differential Gearbox goes back to a 1:1 gearbox. Packaging machines, food and beverage processing machinery and printing machinery often use Harmonic Differentials to time rotary processes that occur in various sections of these machines.

The Harmonic Differential Gearbox is continuously or infinitely adjustable (meaning there is no mechanical stop on the control shaft preventing continuous adjustment) and can also be used for speed trimming applications by applying a constant rotation to the control shaft. The Harmonic Differential because of its efficiency is ideal for narrow range, precise speed trimming and is therefore used in a number of tensioning and draw control applications.

For speed trimming applications, or applications that involve both speed trimming and positioning, the HDC Series from Candy Controls may be a viable solution. Unlike the HDD Series, the HDC Series is not 1:1 with the control shaft held stationary. Depending on the control shaft ratio selected, the HDC Series has a built-in gain or draw, up to 2% of input speed. This built-in gain can be further manipulated (increased or decreased) through a constant rotation applied to the control shaft. Soft anvil die cutting machines may incorporate the HDC series to match web speed as the anvil’s O.D. shrinks as a result of use.

To satisfy the engineer in me, can you do a deeper dive on the principle of operation?

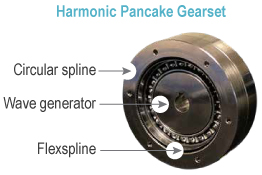

Harmonic Differential Gearboxes incorporate one or two Harmonic gearsets which are precise, high ratio reducers. The HDD Series for example, uses two pancake-type Harmonic gearsets, integrated in a back-to-back arrangement to offset each other’s ratio. The first gearset acts as a speed increaser while the other gearset acts as a speed reducer, the two canceling each other to provide a 1:1 transmission when the control shaft is stationary. Each gearset is comprised of three major elements: a circular spline, a flex spline and a wave generator. One gearset is attached to the hollow inner shaft, while the second is connected to the out housing of the HDD Series. When the control shaft(s), connected to the wave generator(s), is held stationary the HDD Series operates as a 1:1 gearbox. As the internal components of the differential are symmetrical about a centerline, mounting can easily be made at the end of the shaft to be adjusted (or adjacent to it) making the Harmonic Differential Gearbox ideal for machine retrofits. For more detailed information on operation, please refer to the “Principle of Operation”, https://candycontrols.com/products/candy-harmonic-hdd/.

The HDC Series incorporates one cup-type Harmonic gearset. The cup-type components are operationally similar to the pancake design described above. The outer housing of the HDC is connected to the circular spline, while the hollow inner shaft is connected to the flexspline and the control shaft is keyed to the bore of the wave generator. Because there is only one Harmonic gearset, the HDC Series is not 1:1 like the HDD Series. When the control shaft is stationary, the HDC’s hollow inner shaft will have a built-in gain or draw of ½% to 2% of input speed depending on its control shaft ratio. For additional information, please refer to the Principle of Operation for the HDC Series, https://candycontrols.com/products/candy-harmonic-hdc-differential/.

Candy Controls has 60 years of experience helping OEM and MRO customers improve machine productivity through the implementation of differential gearbox technology. If you are researching solutions for your rotary motion control application, please consider a Harmonic Differential Gearbox and contact Candy Controls today to put our experience to work for you.

Candy Controls

Candy Controls