Phase-Adjusting Couplings Improve Machine Productivity

We are all familiar with the old adage, “Timing is Everything.” This is true in many facets of life, and it is especially relevant in industrial automation and manufacturing. In this context, machine timing equates directly to productivity, or lack thereof. What do you do when your production line loses timing? It’s not as easy as adjusting the time on a watch, is it?

Candy Controls, a leading provider of innovative motion control solutions, offers a game-changing product: phase-adjusting couplings. The Phasing Hub and Timing Hub are designed to statically fine-tune the synchronization of different machine components, ultimately leading to enhanced efficiency and productivity. In this article, we will explore how these phase-adjusting couplings can significantly improve machine productivity.

Phasing Hub – Provides infinitely variable, stepless and bi-directional position control between driving and driven shafts. Toolless adjustment is made by manually rotating the knurled outer housing creating a 100:1 ratio travel relationship between input and output hubs. Click here for more information on the Phasing Hub and its principle of operation.

Timing Hub – A low cost phase-adjusting coupling designed for rotary positioning and timing adjustments. The Timing Hub provides static positioning by removing drive bolts and turning the output flange relative to the input flange. Once proper timing is achieved, re-assemble. Click here for more information on the Timing Hub’s principle of operation.

What issues do phase-adjusting couplings address?

There are numerous variables that impact machine productivity. Key variables that most manufacturing processes have in common are the ability to produce quality products, to increase production rates, to quickly set-up and changeover products, to minimize material waste and to reduce downtime.

Longer than the list of variables that determine productivity is the list of typical reasons machines lose timing or synchronization between moving components, resulting in a loss of productivity. Issues like misalignment, shock loading, excessive vibration, thermal expansion, normal wear and tear on gears-chains-belts-bearings, changes in ambient temperature or humidity, E-stops, and machine jams. Component failure can also have significant impacts on the synchronization of manufacturing machines. Phase-adjusting couplings, like the Phasing Hub and Timing Hub, can correct many of these problems almost as easily as you can correct the time on your watch.

Before delving into the benefits of phase-adjusting couplings, it is important to understand the role of couplings in industrial machinery. Couplings are mechanical components used to connect two shafts, the driving shaft and the driven shaft, allowing them to rotate together. Couplings simply transmit power and torque from one part of a machine to another. The accuracy, precision and repeatability of this power transmission are vital for the synchronized operation of various machine components. Traditional couplings, however, maintain a fixed alignment, or phase angle between the driving and driven shafts. As circumstances described above occur, a machine may lose its timing and ultimately its productivity. In this case the traditional coupling is neither the main problem nor the solution.

Phase-adjusting couplings, however, are not always fixed in their alignment between input and output hubs. When the machine is stopped, phase-adjusting couplings can be adjusted by hand to change the position, or phase angle, between input and output hubs and subsequently between driving and driven shafts. Any process powered by the driven shaft can be statically timed or synchronized with a full 360° of bi-directional phase adjustment. Once the machine components are synchronized, the new position can be locked into the Phasing Hub or Timing Hub, and when the machine begins to operate again, the phase-adjusting coupling will rotate with fixed alignment. If further timing adjustment is needed, stop the machine, quickly and easily change the phase angle between the Phasing Hub’s or Timing Hub’s input and output elements and start the machine.

Real World solutions

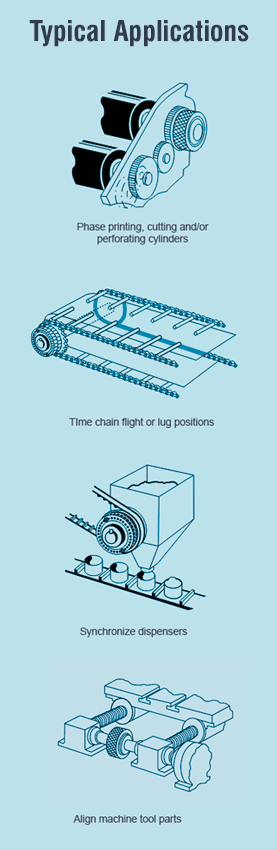

Let’s go a step further and apply what we have covered about phase-adjusting couplings to real-life manufacturing scenarios:

- If product is not being placed accurately on, or in, a tray because the chain that helps position and move the tray through the line has stretched as a result of normal wear, simply reposition the chain and chain flights with a Phasing Hub.

- If a hopper is not properly dropping product into containers on a conveyor below because constant vibration affected the machine timing, adjust the hopper, or the location of the conveyor belt, with a Timing Hub.

- If a printing cylinder is not placing an ink color in the correct location on the web because of material deviation, adjust the rotational position of the printing cylinder with a Phasing Hub to correct registration errors.

- If a cartoner is failing to push product, an ink cartridge for example, into a box because the machine lost timing after an E-stop occurred, adjust the position of the rotating pusher head with a Timing Hub.

- If a linear system with two or more ball screws, racks or other actuators is ratcheting due to physical error, tooth wear for instance, or misalignment during assembly, use a Phasing Hub to help align the system ensuring smooth travel.

- Use a Phasing Hub to tune multiple gear power trains, reducing or eliminating backlash as a result of tooth wear or gear tolerance stack.

- During product changeovers, adjust the position of bottles under a filling head by adjusting the position of the feed screw or by adjusting the rotating filling head with the use of a Timing Hub.

- Adjust the rotary position of die cutting cylinders to correct perforating, cutting or sheeting errors as a result of shock loading with a Phasing Hub.

- After replacing a failed machine component, synchronize fingers that maneuver food product during packaging with a Timing Hub.

Increased productivity translates into increased revenue

Unless your production line is servo driven, loaded with servo motors, drives, sensors, etc., and as a result excessively expensive and complicated, most manufacturing machines and machine components need a way to implement precise angular timing or adjustment to maintain productivity over time. The need for this adjustment can result from various misalignments, shock loads, vibration, normal wear, material deviation, changes in ambient temperature and numerous other scenarios. The Phasing Hub and Timing Hub are unique, low-cost solutions for these timing challenges, regardless of the root cause. Going back to an opening question, yes, in many cases fixing the timing of machines with phase-adjusting couplings is as simple as correcting the time on your watch.

“Timing Is Everything.” Truer words may never have been spoken. A relevant expression that is also true is, “Time is Money”. Machines with proper timing, running productively, will generate more revenue for you. Contact Candy Controls today to learn how Phase-Adjusting Couplings can help you increase your machine productivity.

Candy Controls

Candy Controls