States of Flex: Flexible they may be, but couplings aren’t a one-size-fits-all proposition – far from it, in fact.

Few drive train components are as deceptively simple as a coupling. Two rotating shafts, a coupling to connect the two, and all systems are go – or seemingly so.

Not quite. Operations can sputter – sometimes to a halt – unless couplings can readily contend with the performance requirements of the application. In addition to speed and torque transmission, misalignment among connecting shafts must be considered, among other conditions.

Enter flexible-shaft couplings. While their rigid counterparts are specified when precise alignment is required, flexible couplings are employed when axes are at a slight angle or slightly displaced, either as a result of tolerance build up or the rigors of operations, including bearing wear or structural deflection.

Depending on operations, misalignment may be lateral, axial, angular or skewed. Angular misalignment, for the uninitiated, occurs when shaft centerlines intersect to form an obtuse angle. Lateral misalignment, by comparison, results from lateral displacement among parallel centerlines. Skewed misalignment refers to combinations of angular and lateral misalignment, axial misalignment to the movement of shaft members toward or away from one another, often as a result of thermal expansion or contraction.

Although conditions may vary, the outcome is invariably the same: The greater the misalignment among shaft members, the less efficient the motor is in generating speed and torque. Misalignment also contributes to premature wear, including broken shafts, failed bearings and excessive vibration.

Flexible-shaft couplings accommodate misalignment while transmitting torque between shafts, typically by virtue of a flexible element sandwiched between a pair of hubs. Depending on the configurations, the couplings also may impart exceptional torsional strength, torsional rigidity, and vibrational damping, as well as low moment of inertia.

While the import of these attributes varies among operations, growing demand for high-speed, high-efficiency processing is driving greater demand for high-torque, high-misalignment, low-inertia couplings with minimal compromise to torsional stiffness.

Operations requiring precise motion control, such as those involved in packaging, bottling, and visual scanning and inspection, also require couplings that exhibit zero-backlash. These zero-backlash, flexible-shaft couplings ensure accuracy and repeatability by minimizing play among components. If the motor shaft turns 90 degrees, so too does the ball screw shaft, without lag time. These zero-backlash couplings are often used in conjunction with servo motors, encoders and resolvers where speed, precision and accuracy are critical. Due to the performance requirements, these couplings are often referred to as servo couplings or encoder couplings.

A matter of motion

The degree to which damping, torsional rigidity, and the like are also required depends on the type of motion involved. The majority of manufacturing lines operate in one of two modes: continuous motion or stop and go. Rapid stops and starts, such as those required for filling, typically generate some degree of vibration. Couplings that dampen vibrations, including the curved jaw, not only diminish settling times, but enhance throughput.

By comparison, systems requiring continuous motion and accuracy, such as machine-vision and optical inspection systems, rely on superior torsional strength such as that exhibited by disc couplings.

For obvious reasons, the force required to set a coupling in motion or stop it from moving – also known as moment of inertia – is less an issue with continuous-motion systems than systems that stop and go. For stop and-go operations, lighter – or low-inertia – couplings, such as the aluminum single-beam type, are recommended to minimize wear and reduce energy consumption.

Give and take

Trade-offs are inevitable. Couplings with high dampening capabilities typically exhibit low torsional strength. Zero-backlash can come at a cost to flexibility. And so it goes. Herewith are major flexible coupling types and their key properties.

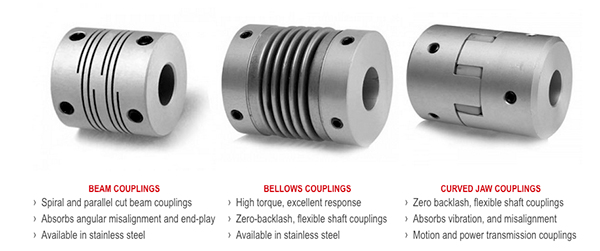

In addition to their damping abilities, curved jaw couplings generally exhibit large torque capacity. The couplings generally consist of a pair metallic hubs and an elastomer insert known as a “spider,” whose hardness can be customized to meet performance criteria. When joined, a jaw from each hub is fitted to the spider’s lobes, with the jaws’ curved profile reducing deformation, thereby limiting the effects of centrifugal forces during high-speed operations.

While jaw couplings can accommodate speeds of 40,000 rpm or greater, they have difficulty accommodating large amounts of misalignment, particularly axial motion. Additionally, large angular or parallel misalignment can create loads on bearing that surpass those of most servo couplings.

Oldham couplings, by comparison, can accommodate relatively large amounts of parallel misalignment, from 0.025 in. to 0.100 in. or more, but only small amounts of angular misalignment and axial motion. They also are limited to speeds of 4,000 rpm.

Though particulars vary, Oldhams typically feature a pair of hubs and a floating center disk made of plastic or, somewhat less commonly, metal. To transmit torque, slots on each side of the disk are mated with tenons on the hubs. As with the jaw coupling, disk materials can be customized to meet specified torque requirements, as well as requirements for damping, zero-backlash and torsional stiffness.

Rather than a center disk, bellows couplings are joined by a thin, flexible wall made of stainless steel or nickel. The wall’s composition limits torque capacity, but readily accommodates angular, axial and parallel misalignment. Due to the wall’s sensitivity, the bellows is well suited to applications involving fine instrumentation. Owing to its torsional rigidity, arguably the greatest among flexible couplings, the bellows also provides a superior degree of precision in rotation. As such, it is well suited to aggressive servo-driven applications.

So, too, are disc couplings, which are available in two formats. While single-disc couplings feature a pair of hubs and a single flat disc spring, double-disc couplings include an additional center spacer sandwiching a pair of disc springs. Both are flexible yet torsionally stiff, but only the double-disc coupling can readily accommodate parallel misalignment. The combination of flexibility and torsional strength makes disc couplings ideal for high-speed operations. However, discs are more delicate than the majority of couplings. Hence, specifiers should ensure that misalignment doesn’t exceed the coupling’s rating.

Beam couplings, like disc couplings, are available in two formats, in this case single and multiple-beams. Each is of a single-piece configuration that transmits torque with zero-backlash, and both include a network of spiral cuts to accommodate misalignment while transmitting torque. Employing a single continuous cut that completes several rotations, the single-beam coupling is sufficiently flexible to accommodate all types of misalignment, although it performs best with angular misalignment and axial motion. It is less successful accommodating torsional loads, a circumstance that can compromise accuracy.

As its name suggests, the multiple-beam coupling consists of two to three overlapping beams, a configuration that allows for shorter beams and, by extension, greater torsional rigidity, with little compromise to flexibility. The overlaps allow the beams to perform in parallel, thereby increasing torque.

Overlap may be the operative word for zero-backlash, flexible-shaft couplings, given the converging concerns they must handily address. As such, specifiers would do well to thoroughly evaluate inherent trade-offs among candidate couplings, just as they would do well to consult with suppliers to evaluate the ways in which the coupling can be customized to optimize its performance.

This is one instance in which product selection and product performance are joined at the hip.

Candy Controls

Candy Controls