CL13 SERIES DESCRIPTION

Rigid Coupling

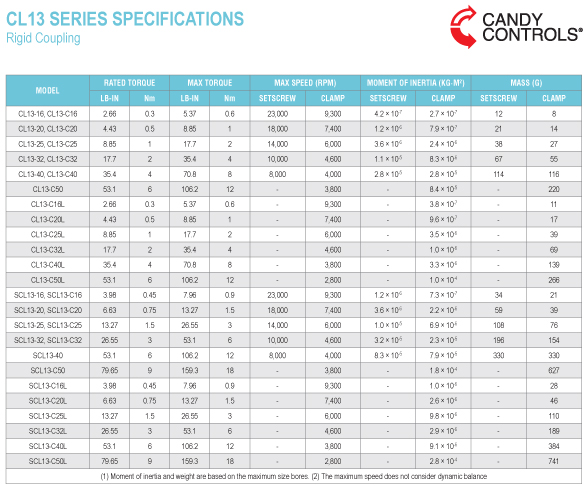

The CL13 Series is a lightweight, extremely low inertia miniature rigid coupling. It delivers high response to optimize motor performance and is available in either aluminum alloy or stainless steel construction, both of which provide high strength and low wear rates for long service lives.

• Setscrew type and clamp type models available

• Engineered with strong, durable materials

• Simple, low maintenance design

• Cost effective servo motor couplings

• Inch, metric and mixed bores

• Custom design and fabrication available

Options

Aluminum 6061 Hubs

Stainless Steel 303

Setscrew

Clamp

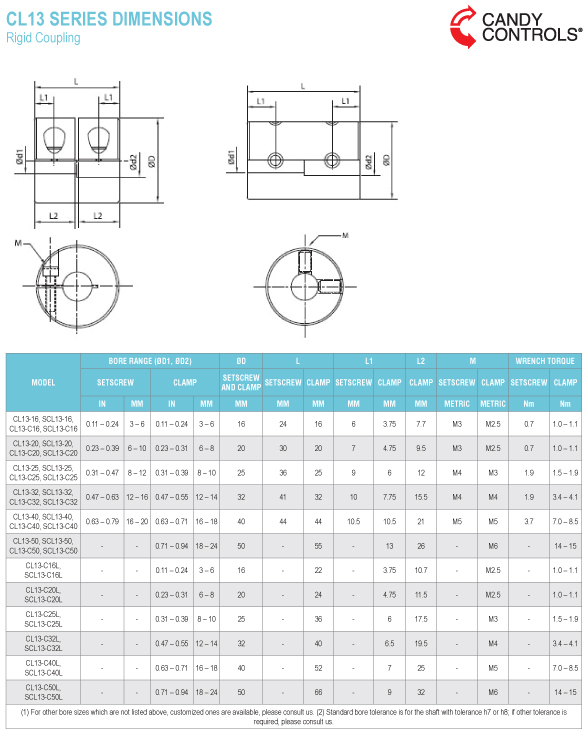

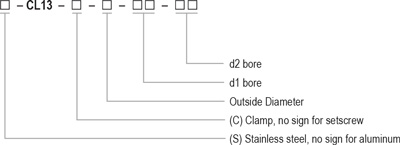

Ordering Information

Back to Top

CL13 SERIES INSTALLATION

Rigid Coupling

Use precautions:

- Please observe the allowable tolerance of eccentricity, angular misalignment and endplay between shafts.

- The bolts must be tightened according to the specified torque.

- The temperature range is -30 to 120 ° C. Rubber elastomers should be kept away from environments with water, oil, acid, etc. Storage or use in direct sunlight may also shorten the service life.

- Do not tighten the clamping bolt before inserting shafts.

Installation:

- Confirm whether set screws or clamping screws are loose, and remove rust, dust and oil on the shaft and the inner diameter of the coupling. Lubricants and contaminants have a significant impact on the friction coefficient of the coupling and must be removed.

- Please insert the coupling onto the motor or driving shaft. When inserting, do not apply too much compression or tensile force on the coupling, especially when inserting the coupling onto the driven shaft.

- When the set screws or clamping screws are loose, please confirm the coupling can move slightly along the axial and rotation directions. If the movement is not smooth, please readjust the centering of the two shafts. This method is recommended as a simple confirmation method of left and right concentricity. If the same confirmation method cannot be used, please use other measurement methods to confirm the installation accuracy.

Candy Controls

When Timing is Everything

Candy Controls

When Timing is Everything